Cut Shipping Damage and Boost Quality Control in China Fulfillment

Shipping damage is one of the easiest ways to lose customers — fast.

Whether you’re selling on Shopify, Amazon, or your own DTC site, damaged products can create refunds, bad reviews, and higher support costs overnight.

If you work with China fulfillment, preventing damage and improving QC isn’t optional.

It’s a core part of keeping your brand reputation strong.

In this guide, I’ll break down the real reasons shipping damage happens and how to fix them before your products leave the warehouse.

Why Shipping Damage Happens More Often Than You Think

Most sellers assume damage happens during the last mile.

But that’s only part of the story.

Damage usually occurs because of:

Weak packaging/Poor cushioning/Low-quality cartons/Lack of QC before shipping/Products not designed for long-distance transport/Mishandling during transit

Once a product leaves the warehouse, it’s handled by multiple carriers, thrown into trucks, and stacked with heavy boxes.

If it’s not protected, it won’t survive.

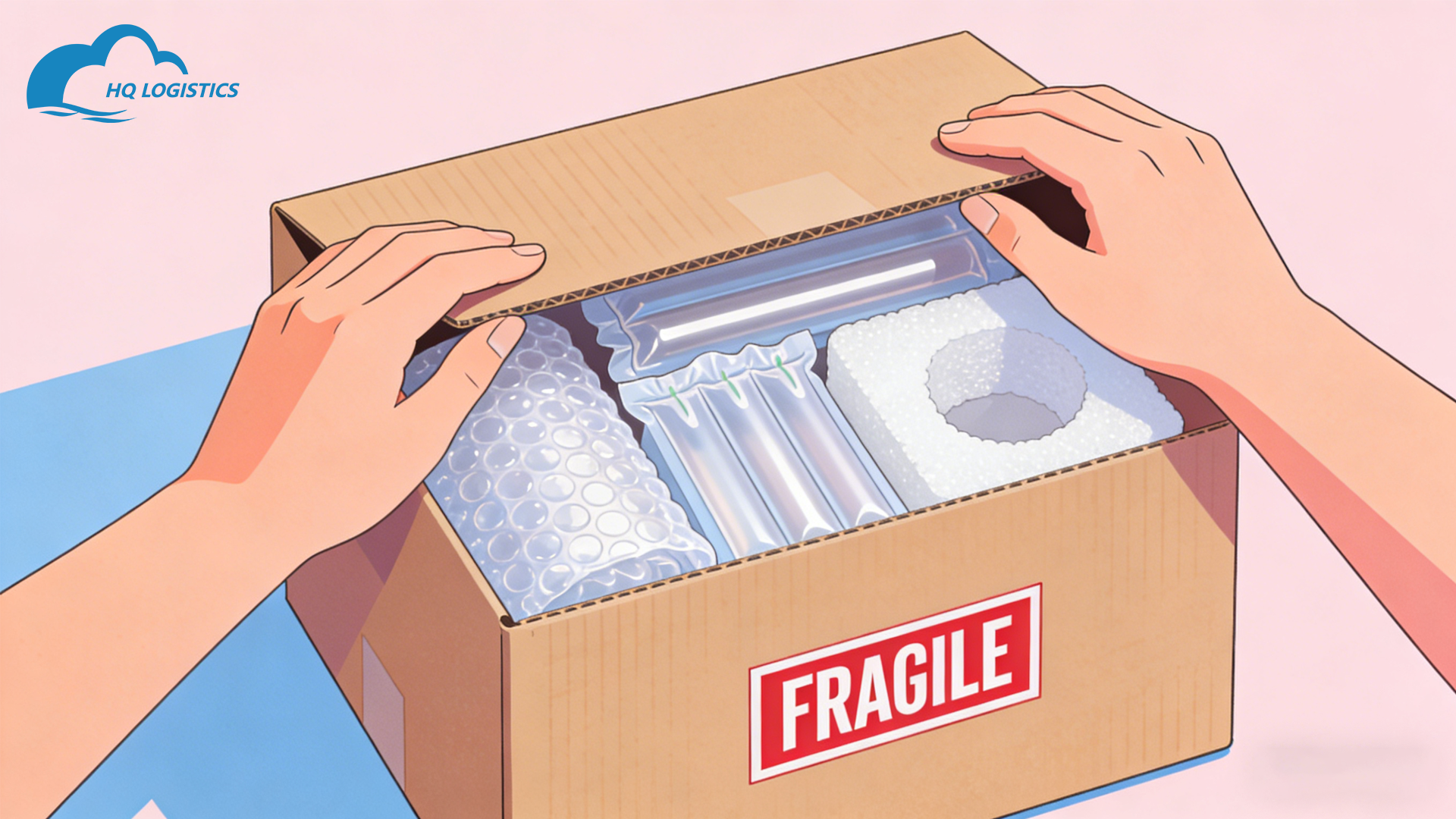

Start with Better Packaging — Your First Line of Defense

Packaging makes or breaks your damage rate.

Small changes have a huge impact.

Here’s what works:

Use thicker corrugated boxes

Add bubble wrap, foam, or air pillows

Avoid oversized boxes (products move too much inside)

Seal edges with strong tape

Add “FRAGILE” or “TOP LOAD ONLY” labels

One brand I worked with reduced damage claims by 42% just by switching to a sturdier carton and adding corner protectors.

If your item is glass, ceramic, or electronic, your packaging must handle at least three drops without breaking.

This is a standard in many 3PLs — ask for drop test photos.

Improve Quality Control at Your China Fulfillment Center

Most issues come from factories, not warehouses.

A strong QC process filters out problems before your customers ever see them.

Effective QC includes:

Checking product finish (scratches, dents, stains)/Testing functionality/Confirming accessories and manuals/Verifying labels and barcodes/Checking packaging seal and branding

/Spot-checking cartons before outbound shipping

A 2–5% random QC rate is good.

For fragile items, increase to 10–20%.

If your 3PL offers professional QC with photos or videos, use it.

It’s cheaper than dealing with returns later.

Use Reinforced Shipping Methods for Fragile Items

Fragile products need stronger protection and sometimes different shipping channels.

Options include:

Double-layer boxes/Extra bubble wrap/Pre-inflated air column bags (great for electronics and glass)/“Fragile-item optimized” shipping lines/Palletizing high-value shipments

Adding $0.20–0.50 of packaging often prevents $20 refunds.

Always ask your warehouse which packaging method they recommend for your SKU.

Prevent Damage During Long-Distance Transport

When shipping from China to the US or EU, products face long-distance stress:

Shock/Vibration/Temperature changes/Compression from stacked boxes

To reduce risk:

Use cartons with higher burst strength

Add interior dividers

Keep products tightly fitted inside the box

Avoid unused empty space

Waterproof the outer layer for rainy seasons

If you ship using sea freight, moisture protection is essential.

Add desiccant packs or anti-mold tablets.

Add Final QC Before Packing — A Game Changer

"Pre-packing QC" means checking the product as it’s being packed.

Benefits:

Ensures no dust, scratches, or factory defects/Ensures correct variant (color/size)/Ensures packaging is clean and intact

/Catches last-minute errors

Many sellers request 1–3 image proofs per order.

It’s a simple way to avoid wrong-item complaints.

Monitor Your Refund Reasons — The Data Never Lies

Your customers are telling you what’s wrong.

Common damage-related complaints:

Product broken/Item scratched/Wrong color or size/Packaging crushed/Missing accessories

Track the data monthly.

If you see a pattern, fix it at the fulfillment center.

One brand discovered 80% of their complaints came from a single fragile SKU — switching to air column bags solved it immediately.

Reduce Shipping Damage With Better Communication

A simple but overlooked tip:

Talk to your 3PL regularly.

Discuss:

SKU-specific packaging/Peak-season handling/Custom protective materials/Testing photos/Special instructions for fragile products

Most warehouses can customize protection — but only if you ask.

Extra Tips to Keep Your Damage Rate Low

Don’t ship without proper labeling

Test your packaging every quarter

Update packaging whenever customer reviews mention damage

Keep heavy items at the bottom of any box

Avoid shipping too many units in one carton

Small improvements stack up quickly.

Short FAQ

How can I lower my product damage rate fast?

Upgrade packaging, increase QC checks, and use better cushioning.

Is China fulfillment reliable for fragile items?

Yes — but only with proper packaging and QC.

Should I pay for extra packaging?

If your item can break, absolutely. It’s cheaper than refunds.

How much QC is enough?

2–5% for normal items, 10–20% for fragile ones.

What’s the most common mistake sellers make?

Using boxes that are too big or too thin.

Final Line

Reducing shipping damage and improving QC in China fulfillment protects your brand, saves you money, and creates happier customers.

📩Email: zoye@fulfllment-cn.com

PREVIOUS RECOMMENDATIONS

Customer's favorable comments is our eternal motivation. We feel grateful for all the support and company.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua.